Benchmarking – What it is and what it is ‘not’:

Benchmarking is the process of measuring a product’s overall performance against those of other businesses that are considered to be the best in the industry. The important aspects of benchmarking are to identify the internal opportunities for improvement, identify the key metrics of the project, assess where the project is currently standing and determine how to create an action plan that necessitates ideal performance. Thus, benchmarking is seen as an essential tool that can assist organizations in developing strong capabilities, ensuring an internal exchange of ideas, and identifying genuine competitive gaps.

Benchmarking VS Competitor study

While benchmarking and competitor analysis may seem similar, they are actually two different processes which aid in understanding any product through steps of data collection and analysis. Competitor research concentrates on performance metrics, while benchmarking concentrates on best practices. Comparative research is viewed as a quick fix that is required to give a process a temporary boost, whereas benchmarking is seen as a tool to create continuous improvements. Benchmarking paves the way for an organization to understand the customer’s needs and provide solutions after examination.

Benchmarking to add a competitive advantage

The future of benchmarking is not seen as the ability to illustrate a few data points or a static set of metrics. We are progressively looking at sensing the data that is collected while learning and adapting to the opportunities that are being displayed from the presented data. Thus, with benchmarking, it is intended to look internally as well as externally and identify emerging trends, which aids in differentiating knowledge from mere commercial hype.

Engineering Importance:

Consultation and proper research to validate a product’s market fit and prioritize the features are extremely important for expected and augmented requirements for a product. With a validated concept, there is an advantage to justifying the practicality of the concept before investing in any resources.

Advantages of the benchmarking process:

Continue to optimize internal operations.

Benchmarking the market’s simulation processes and engineering techniques against internal standards assists an organization in developing a thorough understanding of the processes. This understanding contributes to the development of a broad strategy that is measured at regular intervals in order to create a successful roadmap for upcoming projects. Managers in one department may study the best practices of another.

Compare the performance of various product lines: improved productivity

It is not necessary for benchmarking to involve using competitive intelligence. The performance of facilities and products with comparable processes, as well as metrics and KPIs, is benchmarked by many businesses, especially big and distributed ones. Again, this analysis can lead to more in-depth investigations into the causes of why a specific facility, product, or business unit is performing poorly.

Some common pitfalls in benchmarking for engineering projects

Omitting the formulation of specific goals

Most of the time, manufacturers omit or tend to skip over the crucial step of defining a specific goal or creating unambiguous objectives in favor of evaluating performance. The benchmark analysis falls short of expectations when there is no clear goal. The key objective of the process should be clear. Determining the main goals helps in formulating the correct process. An example would be sales, getting users to sign up for a newsletter, generating donations, viewing ads, or contacting to arrange a service.

Selecting incorrect benchmarks

A very important step in the analysis is choosing the benchmarks itself. It is not advisable to compare the performance of groups or units within a single company or segments in an industry simply because of task completion. Misusing benchmarks can result in poor investment decisions and poor outcomes for investors because benchmarks are not unbiased judges as practitioners portray them to be. Creating customized benchmarks that address the organization’s goals as well as the time horizon and risk tolerance holds significance here.

KPI benchmarking that is excessive

KPIs are effective tools when used as indicators to track progress toward goals. However, if the KPIs become the goals, they become a toxic material that stifles performance improvement. Benchmarking does not follow the adage “the more, the merrier.” It is in fact considered to be a better option not to use KPIs as a catch-all for everything. That will obstruct the analysis and draw attention away from the important elements. So, it is also crucial to fix the KPIs carefully for the benchmarking analysis.

Benchmarking across the industrial segments

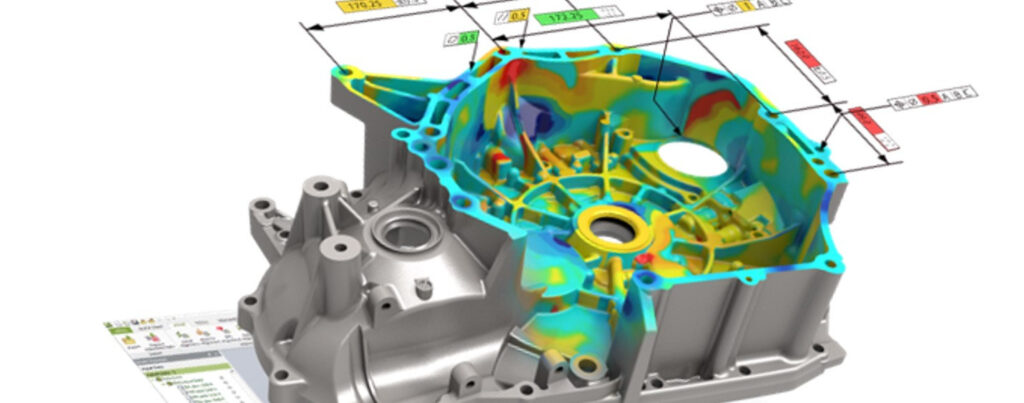

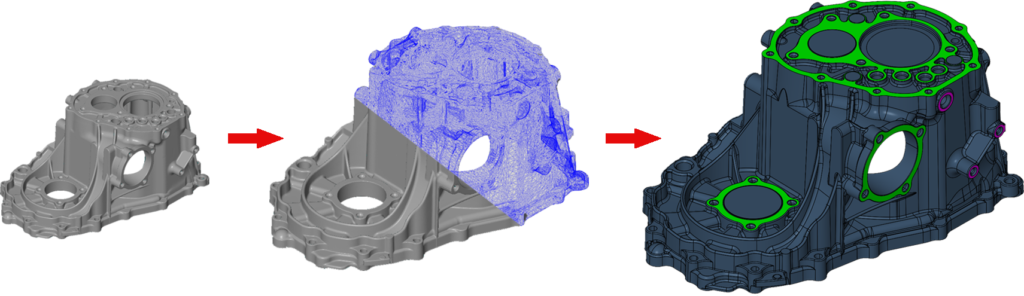

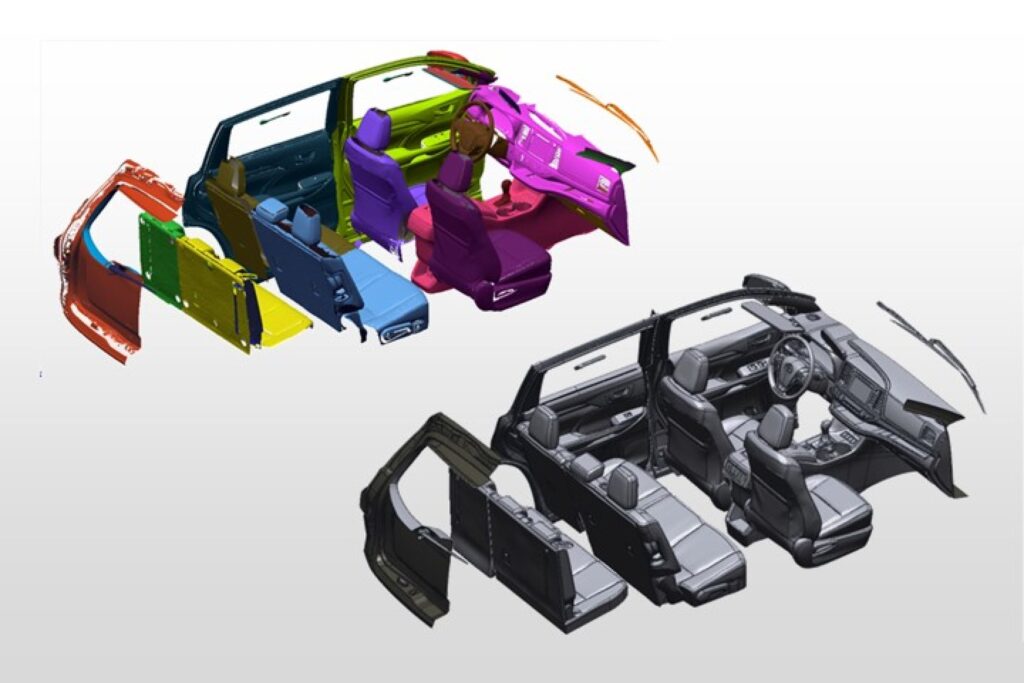

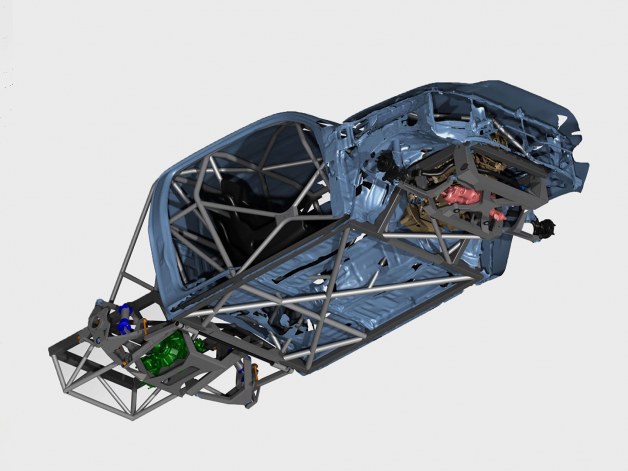

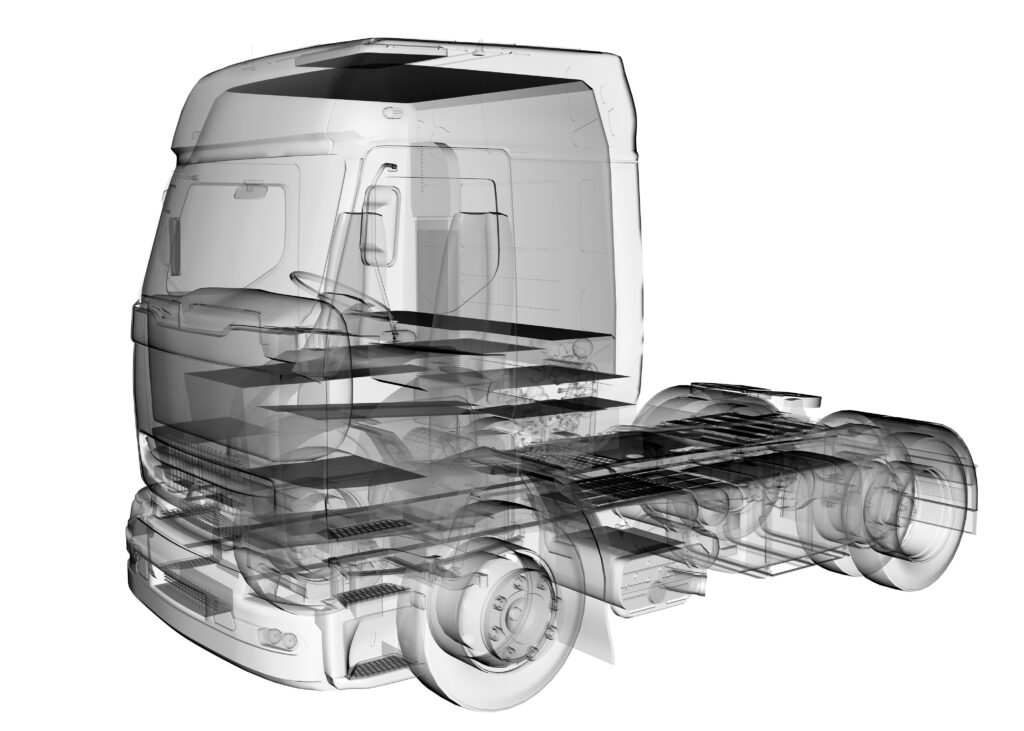

Benchmarking in the automotive industry

To make cars unique and competitive, specific and distinct vehicle attributes are required. As a first step, vehicle manufacturers must benchmark their vehicles in the competitive environment in order to understand and strengthen or improve their vehicles’ potential. This is crucial to comprehending the goal and application of benchmarking. The manufacturing process itself is frequently the focus of benchmarking in order to: increase quality, reduce manufacturing cycle time, reduce waste and rework; and boost output.

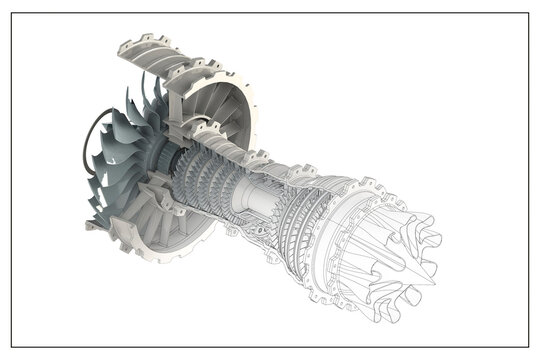

Benchmarking in the aerospace industry

The aviation industry requires advanced, high-quality products at the lowest possible cost. In most cases, working with cheap labor is insufficient to compete. The most advanced products’ technologies, such as turbine blades, composite materials, and fully integrated systems, are closely guarded by the companies that created them. Other types of products’ designs and manufacturing technologies may be more widely available or easier to develop, but the key here is being able to produce them with sufficient precision, quality, and efficiency to be competitive. This is why benchmarking is so important in the aerospace industry.

There is a constant need to strategize and implement appropriate technology that falls in line with the needs of the consumers and delivers state-of-the-art machines.

球速体育’s Benchmarking Services

Data allows organizations to make smarter and more guided decisions. Understanding where the current market leaders stand is becoming more and more important to acquire that competitive edge. As advanced technologies and products are being developed frequently, OEMs are on the continuous lookout for service providers who comprehend their goal of creating best benchmarking approaches and have practical knowledge of market-level research.

We at 球速体育 give our clients top-notch support so they can stay ahead of the competition and develop fresh and new strategies. We take into consideration all the three important dimensions of the product development benchmarking process, such as cost, risk and services. Our holistic services methodology helps our customers to decide and implement the best custom-tailored solutions. We compare processes and capture all of the necessary information using research and analysis. This helps to create benchmark metrics that help take your product development process to the next level. From highlighting the strengths of the ideas to providing insights on best-practices, 球速体育 will ride along with the clients, supporting and assisting in all technology implementation processes.