Challenges with Internal Combustion Engines:

Climate change’s negative impact has compelled humanity to seek ways to reverse global warming caused by greenhouse gases on an ongoing basis. Many countries are considering phasing out internal combustion engine-powered vehicles and enacting policies that encourage the use of electric vehicles in order to reduce greenhouse gas emissions. Internal combustion engines are viewed as a threat to environmental friendly solutions because they emit hot combustion gases that have ignition properties, additional heat productions & energy wastage (exhaust manifolds and piping). Their combustible systems are proven to be inappropriate for an environment containing flammable gases. Additionally we have multi folds of intricate features in these types of engines.

A need for immediate solutions:

We are living in a time where developing sustainable solutions to major challenges, across industries, is a default requirement for any manufacturing organization. And we’re advancing towards solutions like electrification, connected, and self-driving cars. Now we are witnessing significant changes in these emerging trends, but how soon are we expecting the implementation to get completed?

In terms of infrastructure, wide global reach, battery challenges, cost inefficiencies, and short driving ranges, electric vehicles still need progress to compete on-par with conventional vehicles. This is when we must remember that, while we advocate for electric vehicles with emissions as the primary consideration, we must also keep in mind that electric vehicles guarantee only a minimal amount of pollution over longer periods of implementation time. This aspect indicates that even the best-optimized solution will have its own fruitification period. As a result, solution providers are still attempting to provide alternative solutions that are significantly easier to implement at less time.

Improving the efficiency of Internal Combustion Engines:

1.Improving combustion engines in terms of efficiency parameters:

Over the last 30 years, research and development has assisted manufacturers in reducing ICE emissions from various pollutants such as nitrogen oxides and particulate matter (PM) by more than 99 percent in order to meet EPA emission standards. Research has also resulted in improvements in ICE performance (power &acceleration time), allowing manufacturers to maintain or increase fuel economy. (EPA, Jan 10, 2022)

2.Reducing vehicle emission by reducing weight – Lightweighting solutions

Opportunities for lightweighting are also seen as ways to reduce greenhouse gas emissions during the various lifecycle stages of the product. OEMs are looking for new ways to use natural or recycled fiber-reinforced composites as they are light in weigh and require less energy than conventional materials.

Customers should think about purchasing fuel-efficient vehicles. The less the fuel used, the less the smoke that is produced. A lightweight vehicle consumes less fuel because it must overcome less inertia, which reduces the power required to propel the vehicle. Improvements in the overall design of the vehicle, such as aerodynamics design and drive train efficiency, can be directly proportional to the vehicle’s overall weight, influencing emission.

How at 球速体育, we are progressively looking at solutions to reduce emission

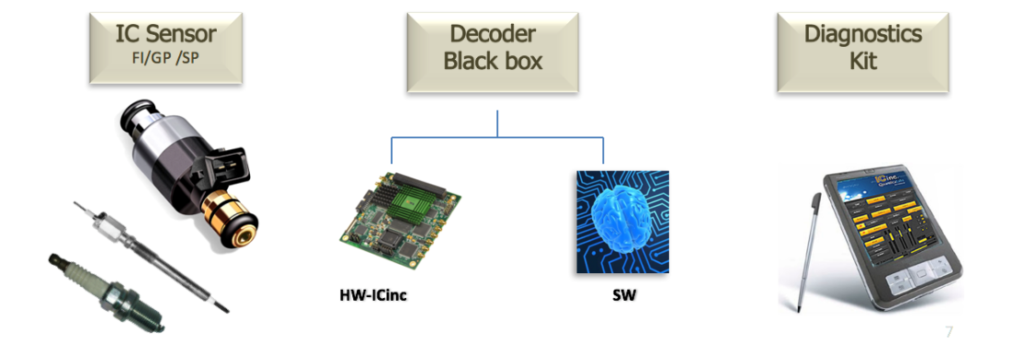

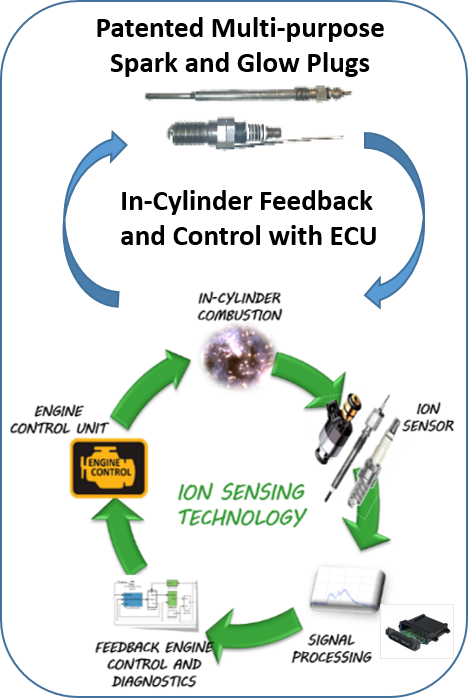

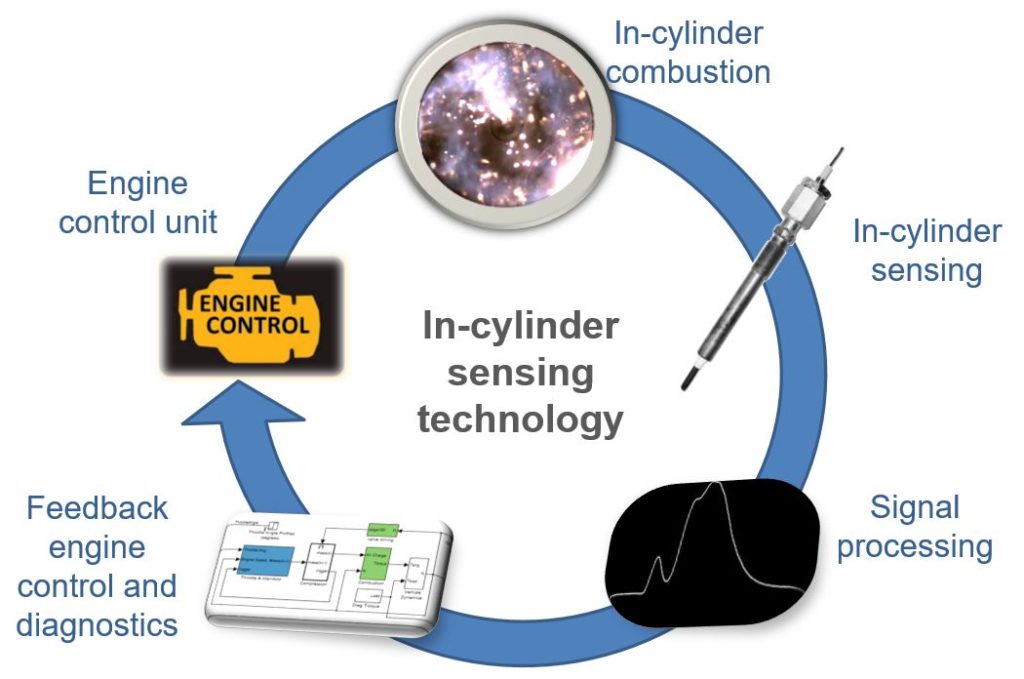

球速体育’s latest technology enables multiple sensing tasks and real-time engine management by providing feedback to the engine’s electronic control to achieve future stringent emission norms and fuel economy standards. This in- cylinder sensor technology aids in the improvement of internal combustion engine efficiency and emission reduction. Pressure sensors, oxygen sensors, and knock sensors could all be replaced by an advanced IC combustion sensor combined with our proprietary advanced algorithms.

With our latest IP algorithms, we have the ability to produce information about engine combustion, performance, and emission parameters on a cylinder-to-cylinder and a cycle-to-cycle basis. All these can be done without the need to drill a hole in the cylinder head, or using a spark or glow plug as the ion sensor. The major advantage of this project is to provide transformational solution that aims to reduce emission and achieve greater fuel economy. Our suite of solutions also aid in creating lighter solutions with mass, shape and design into consideration, substantially cutting down lightweighting time. This aspect will also boost the efficiency for both conventional and progressive product development processes.

To know more about 球速体育 IC Sensor

To know more about Internal combustion engine sensor