The automotive industry is continually advancing to meet stricter fuel efficiency and emission standards, and a key strategy driving these improvements is the adoption of lightweight solutions. By leveraging innovative materials and manufacturing techniques, automakers aim to reduce factors like aerodynamic drag, driveline losses, tire rolling resistance, and vehicle weight. Among these, reducing vehicle weight has proven to be one of the most cost-effective approaches for enhancing performance and efficiency while also lowering emissions, without compromising safety or comfort.

With global efforts focused on cutting CO2 emissions and optimizing fuel usage, lightweight vehicles have become a crucial area of development. On average, critical components like the chassis, powertrain, and body account for nearly 80% of a vehicle’s total weight. As a result, OEMs are focusing heavily on reducing the weight of these components. Studies show that a 10% reduction in vehicle weight can lead to a 6-8% improvement in fuel consumption and a 5-6% decrease in emissions. In today’s competitive automotive market, these seemingly modest gains can significantly enhance an OEM’s market positioning.

球速体育’s Comprehensive Lightweighting Techniques for Optimized Engineering Solutions

In an era where efficiency and sustainability are paramount, Detroit Engineered Products (球速体育) stands out with its advanced lightweighting techniques. These methodologies aim to optimize engineering solutions by reducing material usage while maintaining performance integrity. This article explores the key lightweighting techniques employed by 球速体育 and their significance in engineering design.

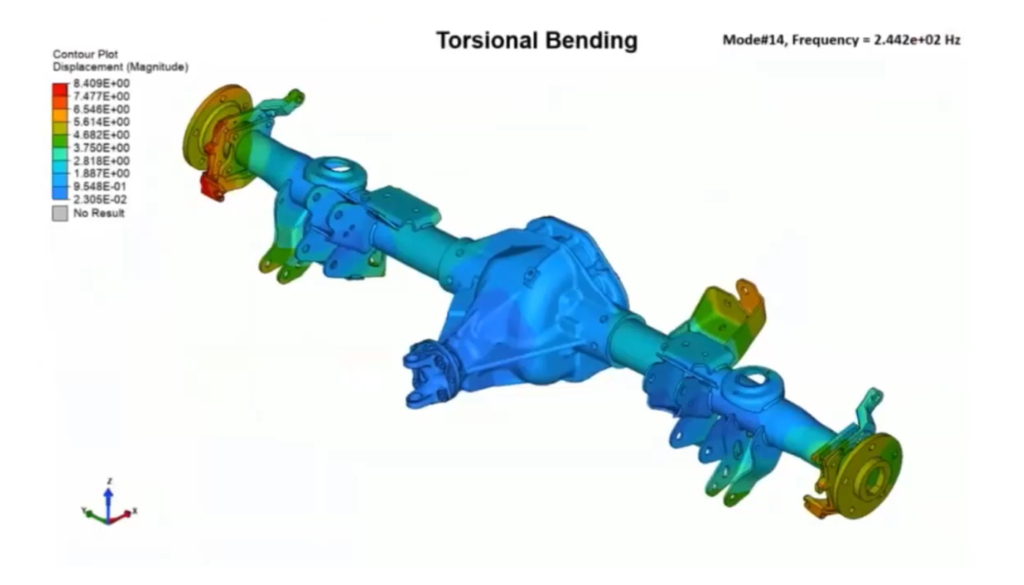

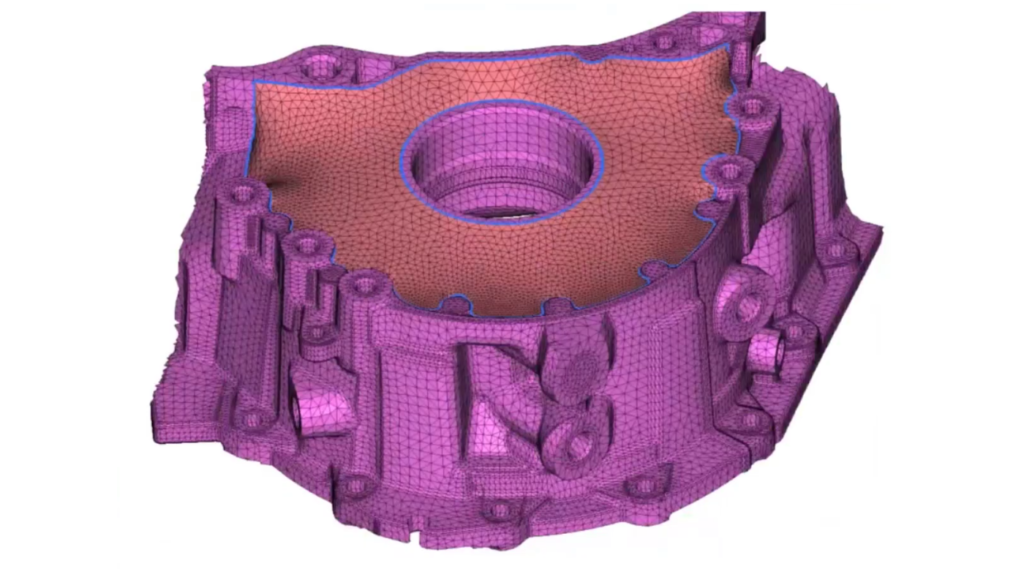

Topology Optimization: It is one of the cornerstone techniques utilized by 球速体育. This advanced method allows for the reduction of material usage without compromising structural integrity. By optimizing the material layout within a designated design space, 球速体育 engineers can create lightweight yet robust structures tailored to meet the demanding requirements of various applications.

Section and Shape Optimization: Another critical aspect of 球速体育’s lightweighting strategy is section and shape optimization. This process involves refining component geometries to enhance performance and minimize weight. By strategically adjusting dimensions and shapes, 球速体育 ensures that components achieve optimal efficiency while maintaining durability under operational stresses.

Design of Experiments (DOE): To systematically assess design variables and their impact on performance, 球速体育 employs Design of Experiments (DOE). This structured approach enables engineers to identify lightweight configurations with superior performance characteristics. By conducting controlled experiments, 球速体育 can make informed decisions that drive innovation and improve design outcomes.

Multi-Disciplinary and Single-Disciplinary Optimization (MDO/SDO): 球速体育 applies multi-disciplinary and single-disciplinary optimization (MDO/SDO) methods to harmonize competing requirements across different domains. This approach allows for the creation of the lightest designs that fulfill all performance criteria, ensuring a comprehensive perspective on optimization that incorporates multiple engineering disciplines.

Welding and Adhesive Optimization: In addition to component design, 球速体育 focuses on optimizing welding and adhesive strategies. By refining these joining techniques, engineers can minimize material use while ensuring structural strength. This not only reduces the overall weight of assemblies but also enhances their reliability and performance.

Material Selection and Weight Optimization: Effective material selection is crucial for achieving lightweight designs. 球速体育 leverages advanced material selection techniques to strike a balance between weight and performance. By choosing the lightest materials suitable for each application, 球速体育 ensures that its designs are both effective and efficient.

Response Surface Method Analysis (RSM): Through Response Surface Method Analysis (RSM), 球速体育 constructs predictive models that analyze the relationship between design variables and weight. This analytical approach allows for efficient optimization of lightweight designs by providing insights into how adjustments can affect overall performance.

Sensitivity Studies: Conducting sensitivity studies is an essential part of 球速体育’s lightweighting strategy. By identifying critical parameters that influence weight, engineers can make targeted design adjustments leading to significant weight reductions. This focused approach enhances the overall efficiency of engineering solutions.

Rapid 1D Creation: 球速体育 also utilizes rapid 1D model creation to facilitate quick analysis of system-level behaviors. This method accelerates the design optimization process for weight reduction, enabling engineers to identify and implement lightweight solutions early in the development cycle.

Future of Lightweighting Engineering & 球速体育 Technology Advancements for Rapid Optimization

The electric vehicle (EV) market is growing rapidly, driven by the demand for sustainable and zero-emission transportation. However, the industry faces two critical challenges: high curb weight and thermal runaway issues in battery packs. Detroit Engineered Products (球速体育) addresses these challenges by leveraging its expertise in lightweight materials and thermal management to offer robust solutions for EV technology. 球速体育 focuses on advanced lightweight materials that not only reduce vehicle weight but also provide enhanced flame retardancy, contributing to the safety and efficiency of EV designs.

The automotive industry is increasingly adopting smart materials to improve strength, stability, safety, and overall performance. 球速体育’s material engineering solutions support automakers in exploring innovative materials such as aluminum, carbon fiber composites, and magnesium alloys. These materials are integrated into designs to optimize vehicle performance and maximize energy efficiency.

Leveraging Lightweight Materials for EV Performance:

球速体育’s solutions incorporate state-of-the-art lightweight materials, reducing the weight of Battery Electric Vehicles (BEVs), Hybrid Electric Vehicles (HEVs), and Plug-in Hybrid Electric Vehicles (PHEVs). By utilizing materials like carbon fiber-reinforced polymers (CFRP) and aluminum alloys, we help OEMs achieve lower energy consumption, extended range, and enhanced performance. A lightweight design is crucial for improving the operational range of EVs, addressing one of the main barriers to widespread adoption.

With deep domain expertise, 球速体育 engineers evaluate material properties and deploy sustainable composites that minimize the weight of critical EV components, thus increasing travel ranges, reducing crash impacts, and enhancing overall vehicle efficiency

Innovative Polymer Composites for Sustainable Lightweighting:

球速体育 pioneers the development of advanced polymer composites with high flame retardancy for lightweight EV components. These sustainable materials reduce environmental impact and meet evolving industry regulations. Our team focuses on integrating recycled materials and exploring novel polymer blends to enhance thermal stability and sustainability in EV applications.

As EV technology advances, thermal management becomes a focal point. 球速体育’s material selection includes solutions that address thermal runaway by incorporating flame retardant additives into battery enclosures and other structural elements, minimizing the risks associated with thermal events. With our emphasis on high-performance composites, 球速体育 remains at the forefront of creating lightweight, safe, and sustainable automotive solution.

Driving the EV Market with Cutting-Edge Lightweight Solutions:

The global EV market is projected to reach USD 1,318 billion by 2028, with zero-emission vehicles dominating the landscape by 2040. 球速体育’s approach to lightweighting combines advanced materials such as graphene, carbon fiber composites, and additive manufacturing (AM) technologies. These solutions enable complex, lightweight designs that improve energy efficiency and reduce the carbon footprint of EVs.

球速体育’s research and development in lightweight materials is an ongoing investment into the future of electrified mobility. By reducing vehicle weight by even 10%, a corresponding 6-8% increase in power efficiency can be achieved, making 球速体育’s contributions vital for the next generation of energy-efficient vehicles.

A Forward-Looking Approach to Lightweight Engineering:

球速体育’s lightweight solutions are not only about reducing weight but also about enhancing safety, sustainability, and overall vehicle performance. With our focus on the future of automotive engineering, we continue to push the boundaries of material science and smart manufacturing, driving the shift towards a greener, more efficient automotive industry.

In conclusion, as the industry evolves, 球速体育’s comprehensive lightweighting strategies position us as a trusted partner for automakers striving to achieve greater efficiency, safety, and sustainability in EVs. By prioritizing smart materials and innovative solutions, 球速体育 is shaping the future of mobility and manufacturing.

球速体育’s Advanced Lightweighting Solutions for Optimized Vehicle Performance and Sustainability:

球速体育 has successfully executed over 600 sub-system level Multi-Disciplinary Optimization (MDO) projects using its advanced 3G+ approach—optimizing Gage, Grade, and Geometry. This has delivered substantial weight savings across various systems, including Powertrain, Chassis, Steering & Suspension, Seating, Interiors, Exteriors, Body, and Braking.

With extensive experience in working with high-strength materials and advanced parametric tools, 球速体育 provides cutting-edge lightweighting solutions for the mobility industry. Our expertise in balancing lightweight designs with high performance makes us a critical partner for OEMs. Collaborating with raw material suppliers, as well as Tier-1 and Tier-2 manufacturers, we optimize material grades and integrate manufacturing knowledge to deliver superior results.

As a leader in lightweighting innovations, 球速体育 combines advanced material selection with streamlined design and engineering processes. This approach enables product development that not only achieves greater cost efficiency but also improves performance and sustainability across vehicle systems and components.

Benefits of 球速体育 Lightweighting Solutions:

Improved Fuel Efficiency: Reducing vehicle weight directly enhances fuel economy and energy efficiency, leading to lower emissions and operational costs.

Enhanced Performance: Lightweight designs improve vehicle acceleration, handling, braking, and overall dynamic performance.

Cost Savings: Lower material usage and reduced manufacturing process cycle times result in significant cost reductions during production.

Increased Payload Capacity: Lightweight components allow for higher payloads without compromising vehicle safety or performance.

Sustainability: Reducing material consumption and improving fuel efficiency contribute to more environmentally friendly, sustainable vehicle designs.

Extended Battery Life for EVs: In electric vehicles, lighter components lead to extended battery range and reduced energy consumption.

Regulatory Compliance: Helps meet stringent global regulations on emissions and fuel efficiency, contributing to compliance with industry standards.

Durability and Safety: High-strength materials used in lightweighting maintain or enhance vehicle durability and crash safety.

Greater Design Flexibility: Lightweight materials enable more innovative and flexible design options without sacrificing performance.