Present age of Li-Ion Batteries:

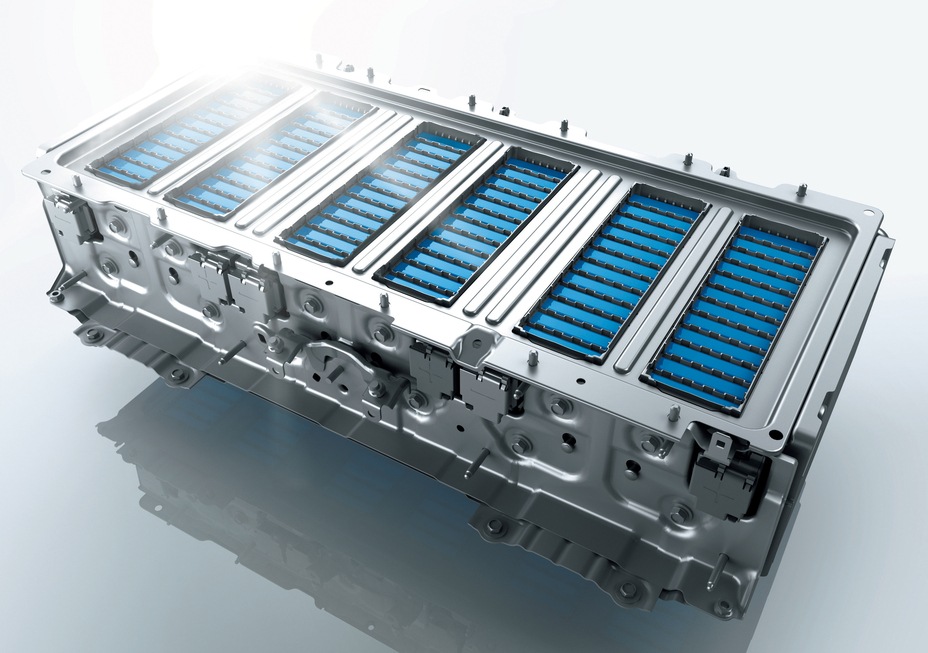

Manufacturers predict that lithium batteries will continue to be the lead role player in battery material types with some variants in composition, due to the demand for safer and more durable batteries. Because of their light metal composition and strong electrochemical potential, these lithium-ion battery types are regarded as the front-runners in the battery race. When compared to other batteries, lithium-ion batteries have shown to produce the most energy per unit of volume. Tagged as a ‘best’ battery material, it is employed not only in automobiles but also in consumer electronics like PCs, laptops, mobile phones, ear buds, and other devices.

However, when exposed to high temperatures, the liquid electrolyte found in conventional lithium-ion batteries poses a safety risk. As a result, the suggestion to replace the electrolytes state is considered. Additionally, switching from liquid to solid electrolytes could produce significantly better outcomes.

Future Choices of batteries:

Recent advancements in batteries and battery management methods are developed based on their effective application in ‘electrification’. Consumers are not interested in purchasing electric vehicles with shorter battery life/run-time and other driving-related complications. With the battery being the major component of attraction in EVs, it is driving manufacturers’ interest towards alternative long-lasting lithium-ion battery options which are also safer.

The following are some other battery types that are gaining more and more popular as alternative power sources.

Lithium-Sulfur Batteries:

The negative electrode in a Li-S battery is made of metallic lithium, and the positive electrode is made of sulfur. This explains why it has a theoretically higher energy density than lithium-ion by a factor of four. The aerospace industry can profit a lot from this particular factor. The technological upper hand of this route eliminates the main drawbacks of the liquid-based Li-S and provides extremely high energy density and long life. Despite the fact that these batteries haven’t been used yet, significant technological obstacles have already been overcome, and the maturity level is moving very quickly towards full-scale prototypes.

Sodium-ion batteries:

Na-ion cells outperform lithium-ion (Li-ion) cells in terms of performance and safety over a wider range of operating temperatures despite having a lower energy density and cycle life. Na-ion cells are anticipated to be at least 20% less expensive than lithium-ion batteries. They operate on a similar principle. But Na-ion batteries can still be considered expensive due to their potentially high separator and electrolyte costs.

Flow batteries:

Flow batteries make use of the electricity-producing potential of specific liquids in motion. Although the technology is not brand-new, the initial formulations were cumbersome and large. Efforts have been made by innovators to reduce scale, increase efficiency, and add a beneficial cost tag. These batteries are considered really attractive when leveling and stabilizing applications for electric power companies such as factories and office buildings that require increased capacities of power source, uninterrupted supply, or back-up power.

Battery – Components & Analysis:

Battery Management System – For Better Durability & Performance:

The battery management system protects the battery from overcharging, deep discharging, overloading, under temperature, temperature and short circuits. The management system ensures that the cells in the battery are at the same state of charge (SoC) making the battery run at full capacity. It also communicates with other devices helping to check the battery health and historical data online. The battery management system consumes very low self-power mostly about 5 mill watts for its functioning. The battery management system also provides thermal management to the battery, safeguarding it against over and under-temperature. The Battery management system can measure the different figures such as current, voltage, temperature, and coulomb with which the management system can assess the health of the battery and adjust operations to protect the battery and its package contents.

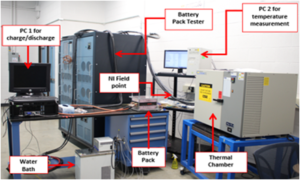

On a deeper level of technology & backend analysis the below processes are required for optimized battery design & performance:

CFD Simulations for complex battery systems:

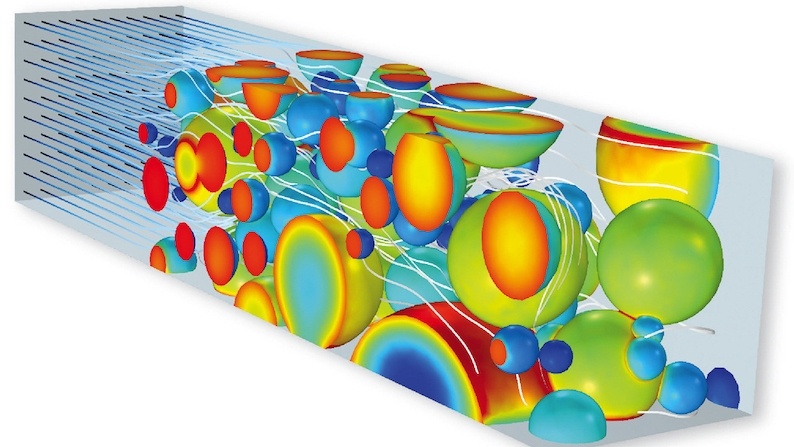

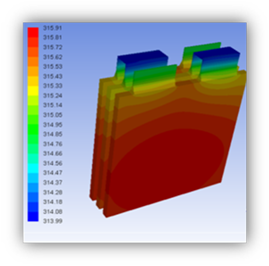

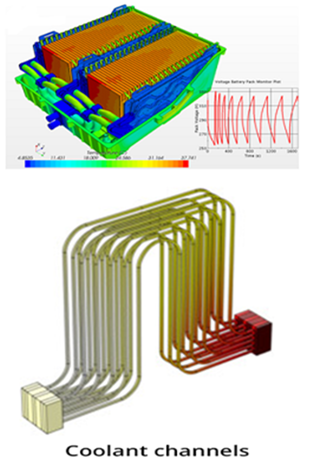

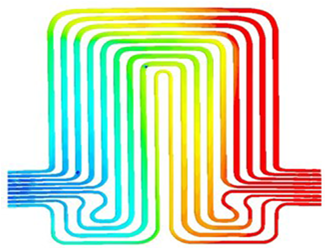

Managing the charge/discharge cycle and controlling battery heat built-up are the two main areas of concern in battery management. The battery management system of EVs has been the subject of numerous coolant studies. It has been determined that the main cause of the working temperature increase is because of the heat generated during the battery operating cycle. A useful tool for examining thermal properties and simulating various ‘physics’ factors is computational fluid dynamics (CFD). Detailed information about the electrical and thermal areas inside the battery during operation is frequently difficult to assess and extract. Using experimental methods, these processes are virtually simulated using CFD methods.

The Thermal Aspects:

The performance of batteries is greatly influenced by temperature which in-turn impacts the charge acceptance, energy capability, reliability, and other battery systems. So, one of the most important technical aspect of any ‘best’ battery system is to prevent overheating and to maintain the ideal working temperature for the battery’s safe operation. The sudden increase in the temperature is indicated as a possibility for thermal runaway which reinforces the management system to then stop the energy flow and alert the problem so that it can be contained before it gets out of control.

Significance of electrochemistry and material selection in battery R&D:

An optimized & well-selected battery material composition plays a pivotal role in developing shorter charging times for batteries, more energy & power capacity along with longer battery life. The integration of contemporary control theory and electrochemical models enables batteries to operate safely in accordance to the material composition limits. This aspect of the chemical/physical properties acts as a key to realizing sophisticated modeling for batteries & its components.

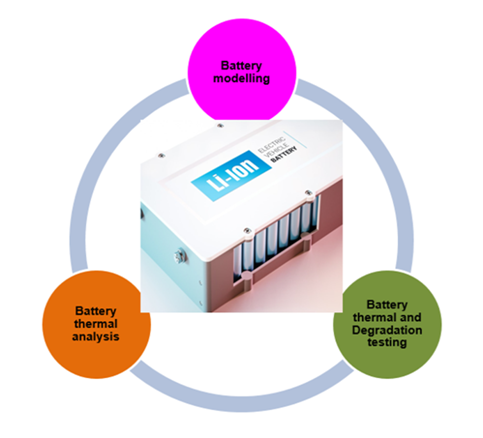

球速体育’s Battery Modeling & Simulation Suite:

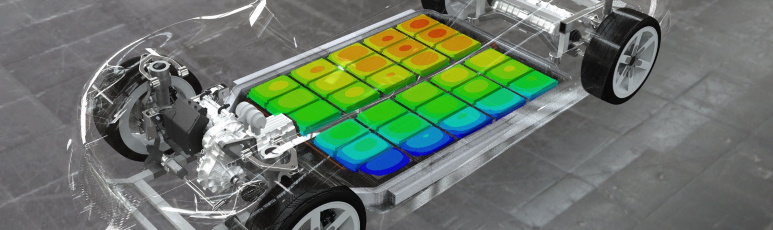

From mobility to consumer products, every battery application comes with its own set of design complexities. With 球速体育 team’s industrial background and technical expertise, battery manufacturers can gain the competitive edge & become industry leaders without compromising on safety, cost, performance & quality. 球速体育 provides holistic battery simulation solutions covering a wide array of battery systems starting from cell and module level analysis to battery pack analysis. Our multi-disciplinary aspects of the simulation study not only supports in cost reduction but advances the time-to-market. The 球速体育 Engineering team, can create customized suite of solutions to analyze a large number of operating conditions and design parameters for electrochemical studies on batteries, fuel cell systems and electrolytic processes depending on customer requirement. We support in understanding the design limitations & provide an optimized solution that improves performance in various operating conditions.

Some of the major areas of Battery Systems where 球速体育 can provide assistance includes:

- Battery Thermal Management – Electro-chemistry Analysis, Coolant Structures, etc. that mainly provides significance in power storage while reducing cost, weight & size.

- Battery Design – Simulation support to build a safe & best performing battery for various industrial applications.

- BMS Development – Developing & testing various integrated systems using a model-based approach, especially for Control Systems, Battery Circuits, etc.

- Battery EMI/EMC Simulation & Testing – Optimizing battery system by early identification of interferences caused by electromagnetic components.