球速体育’s MeshWorks-powered digital twin solutions optimize every stage of product development, from design validation to process refinement and performance enhancement. By integrating advanced CAE techniques and automation, manufacturers can accelerate development cycles, improve product quality, and reduce costs. With early issue detection and simulation-driven insights, 球速体育 helps companies drive innovation and maintain a competitive edge in modern manufacturing.

MeshWorks Application For Manufacturing Processes:

MeshWorks enhances the accuracy of manufacturing simulations by addressing defects such as springback in stamping, wall thinning, and various challenges in injection molding, casting, additive manufacturing, and machining. It refines nominal FE models to map and compensate for distortions through parametric adjustments, effectively mitigating these issues. At the assembly level, MeshWorks extends its capabilities by capturing distortions like weld-induced material property changes from scanned data. Using advanced morphing techniques, it automatically aligns the model to the target shape based on scan data, reducing distortions through compensation and parametric modifications. By updating FE models at both part and assembly levels, MeshWorks plays a crucial role in ensuring manufacturing accuracy, minimizing defects, and improving overall product quality.

Use Case Scenarios:

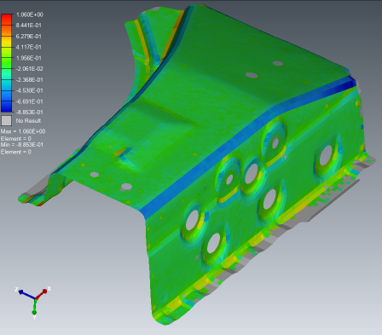

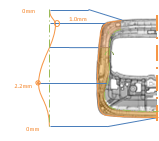

Reverse Windage Compensation Correction

- Morphing is applied to distortion-prone areas.

- Distortions are mitigated to enhance accuracy.

- Reverse windage compensation improves structural integrity.

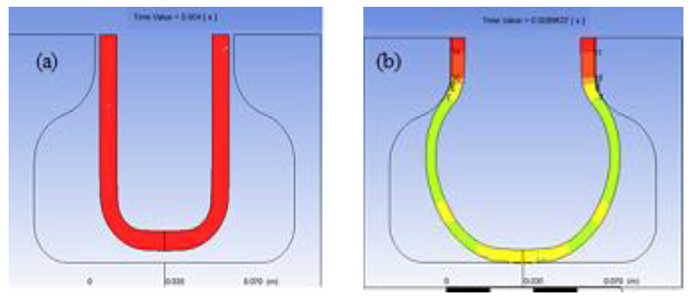

Parameterization for Shape Optimization

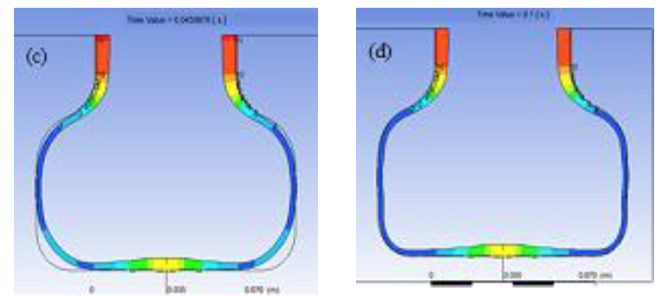

in Blow Molding

- Simulate and predict bottle structural performance and fluid flow characteristics before production.

- Optimize bottle geometry parameters using DOE methodology within 球速体育 MeshWorks.

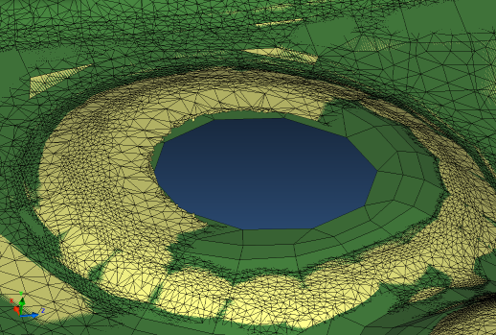

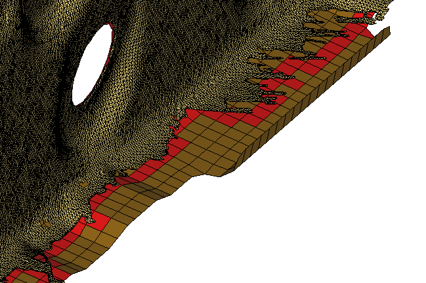

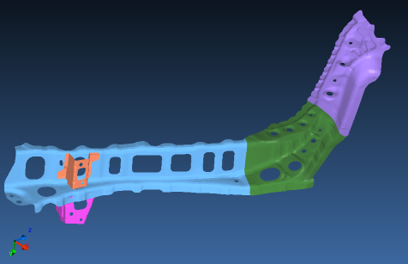

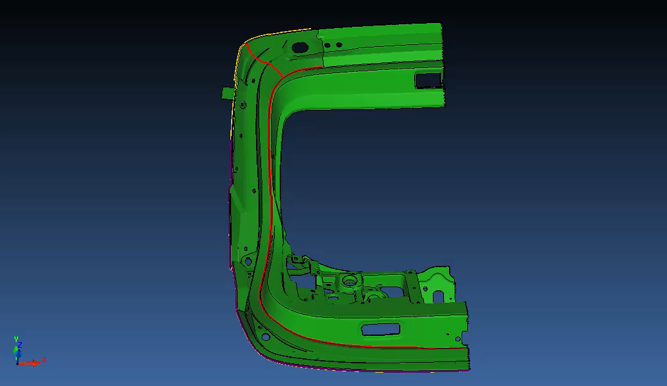

Effective Transfer of Scan Data into a 3D Model

- Morphing Mesh to Scan Data.

- Automated Feature Alignment

- Generating Mid-Surface / Volume Meshes

- Mesh Quality Enhancement

- Import scan data in STL format.

- Append nominal FE mesh model onto scan data.

- Use Process Automator for automatic control and deformable node & element sets.

- Maintain critical features such as welds, holes, and beads during morphing.

- Align mesh data accurately to scanned geometry.

- Enhance mesh quality and ensure consistency.

- Automated morphing of nominal FE models onto scan data.

- Automatic identification of target surfaces, even with scan defects and noise.

- Retains part gaps and stack-up order.

- Automated detection and morphing of slots/holes based on circle centers.

- Optional mid-surface offset adjustment based on property thickness.

MeshWorks Manufacturing Advantages:

- Enhances accuracy with upgraded FE models.

- Provides a precise manufacturing digital twin.

- Reduces geometric variations for consistency.

- Speeds up morphing with automated processes.

- Identifies target surfaces accurately, even with scan defects.

- Maintains part gaps and stack-up order.

- Morphs slots/holes precisely based on circular centers.

- Offers optional mid-surface offset based on thickness properties.